Dock Plate Selection Guide

Choosing the correct SIZE and CAPACITY of loading dock equipment helps improve your loading dock operation. The following guidelines will help you determine what dock equipment best suites your individual needs.

Length

Length

To determine the proper length of dock board / dock plate, three items are required:

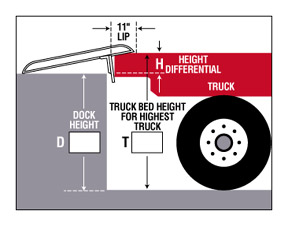

- Dock height (D)

- Available in two capacity ranges

- Height of highest truck (T)

- Type of loading equipment used

Width

Width

Bluff recommends a minimum product width of 12" to 18" wider than the overall width of the vehicle or pallet used. For improved end loading efficiency, you may consider increasing board width, as shown in diagram.

Height Differential

Height Differential is equal to: The maximum height of most trailers (55") minus YOUR dock height (you measure this). On refrigerated or container trailers, use 59".

Length Chart

| Height Difference | DOCK PLATE LENGTH | DOCK BOARD LENGTH | |

| Pallet Jack | Propane Forklift | Electric Forklift | |

| 3 | 36" | 36" | 36" |

| 5 | 48" | 36" | 48" |

| 7 | 60" | 36" | 60" |

| 9 | - | 60" | 78" |

| 11 | - | 72" | 90" |

| 13 | - | 84" | - |

| 15 | - | 96" | - |

Capacity Selection Chart

| 3-Wheel Forklift Capacity | 4-Wheel Forklift Capacity | Board Capacity |

| 2,000-2,500 | 2,000-3,000 | 10,000 |

| - | 3,000-4,000 | 13,000 |

| 3,000-3,500 | 5,000 | 15,000 |

| 4,000-5,000 | 5,000-6,000 | 20,000 |

| 6,000 | 7,000-8,000 | 25,000 |

| 6,500-7,500 | 8,500-10,000 | 30,000 |

| 8,000-10,000 | 10,000-13,000 | 40,000 |

Capacity

- Stackers and other narrow aisle loaders should not be used on a dock board.

- Paper roll clamp and multi-shift loading add 5,000 pounds to the board capacity.

- Capacity rated for single-shift operation at a 3 mile per hour maximum rate of travel.